“If it works in arctic conditions, it works anywhere”: The Nordic push to electrify timber transports

The electrification of forestry transport is no longer a distant aspiration. Across Europe, momentum is building as EU climate targets, industrial competitiveness, and the urgent need to cut fossil-fuel emissions push the sector toward cleaner logistics.

Not long ago, the idea of electric harvesters, forwarders, and timber trucks might have seemed distant. Yet Niko Hannula, Quality Manager of Forest Finland at Stora Enso, reminds us that what was once a vision could become everyday reality as the 2030s approach.

“Today, forestry machines, timber trucks, and raw-wood transports to factories still run largely on fossil fuels. The industry wants to change this,” Hannula wrote in a Forest.fi blog post in August.

Hannula points to the importance of growing collaboration around major initiatives in Europe, such as the seven-year EU-funded Accelerating Climate efforts and Investments (ACE) project, which aims to break down the barriers to electrifying heavy transports in Finland.

The carbon cost of moving Europe’s timber

Logistics in the forest industry is a major source of emissions. Each year about 80 million tonnes of raw materials and forest products are transported in Finland, the vast majority by road.

A similar pattern appears in other forest-rich countries—Sweden, Germany, and Austria among them—where timber and paper products still move primarily by trucks fuelled with diesel rather than rail, biogas-based or electrified forestry transport.

According to a report by AFRY Management Consulting, commissioned by the Finnish Forest Industries Federation, total emissions from forest-sector logistics amounted to 1.9 million tonnes of carbon dioxide in 2022. Meanwhile, Statistics Finland reports that domestic transport emissions overall reached about 9.4 million tonnes of carbon dioxide equivalent in 2023.

Electrification cuts emissions inside mills

Studies demonstrate that electricity is well suited for driving within factory areas as well as for short, standardized, and regular routes. On the other hand, long, heavy timber transport is still waiting for the development of charging infrastructure and more practical experience, especially in winter conditions.

According to a report published by Metsäteho Oy, a Finnish forest-industry R&D company, electrifying 20 percent of timber transports and 25 percent of wood-chip transports could cut emissions by 43,000 tonnes of carbon dioxide per year in use, or 56,000 tonnes well-to-wheel.

“In Finland’s forest sector logistics, this would be a significant step toward carbon neutrality,” says Metsäteho’s senior researcher Pirjo Venäläinen.

Venäläinen stresses that the biggest obstacle to a rapid transition is the charging infrastructure, which is still under development.

“In Finland, the construction of charging stations even near the main road network is just beginning. Infrastructure is precisely the most painfully visible bottleneck for electrification,” Venäläinen notes.

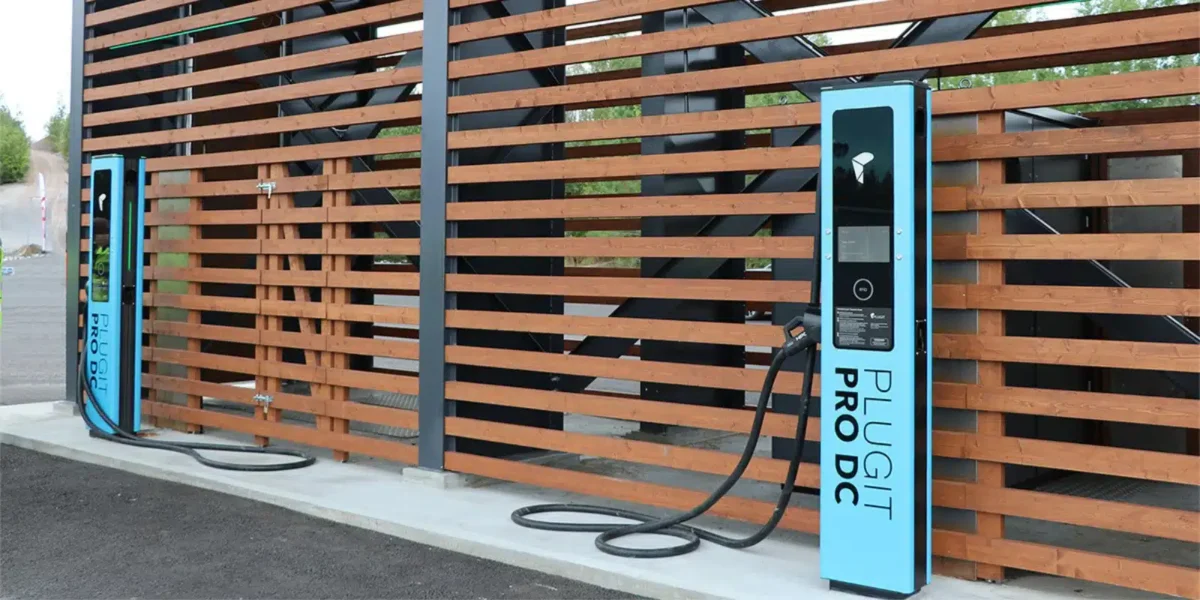

She adds that forest industry companies’ own production facilities could serve as charging hubs in the future. This trend is illustrated by the fact that UPM has already built an electric charging station for heavy-duty vehicles at the Alholma sawmill area in Pietarsaari. Meanwhile, Metsä Group has implemented a similar solution at its Kemi factory area in Lapland, Northern Finland.

Testing the limits of electrified heavy transport in arctic conditions

The green transition of the Finnish forest industry is being accelerated by the ACE project, funded from the EU’s LIFE programme, which aims to support the achievement of carbon neutrality by 2035, particularly in agriculture, heavy transport, and industrial energy use.

In accordance with the EU Climate Law (2020), the EU must reduce net emissions by at least 55 percent by 2030. Venäläinen stresses that the EU’s emission reduction obligations will increase in heavy transport in general – a trend that will inevitably also affect forest industry logistics.

However, a rapid transition to electric heavy-duty vehicles remains unlikely, partly because cost is still a major barrier. An electric tractor unit currently costs about twice as much as a diesel model. According to Metsäteho’s calculations, electrified timber transport is still 7–11 percent more expensive—and electric wood-chip transport 6–8 percent more expensive—than diesel.

The situation can change rapidly, though.

“If electricity prices were 15 euro cents or less, Metsäteho calculations show that the total cost of electric timber combinations would be lower than diesel combinations,” Venäläinen points out.

Stora Enso’s Hannula notes that investment in heavy-duty electric transport in Finland has so far been closely tied to government subsidies. When purchase incentives were available, operators proceeded with electrified truck investments. However, once the subsidies ended at the end of 2024, several companies reported postponing decisions, highlighting the importance of continued financial support to accelerate the transition.

“If we truly want to accelerate the transition in Finland, the operations must become more cost-effective than they are today.”

“This means, for example, more public and private investment in charging infrastructure so that we can invest in electric vehicles,” Hannula says.

Pilots: The crucial bridge in the green transition

Pilot projects are essential stepping-stones in the shift toward low-emission forest logistics. Without hands-on trials, it is impossible to know how electric machinery will perform in real operating environments—especially in the Nordic region, where freezing temperatures, steep terrain, and remote forest roads push equipment to its limits.

If the next generation of zero-emission transport can prove itself in these conditions, the competitiveness of Finland’s along with other Nordic countries’ forest industries could increase significantly.

Reliable electric machinery would shrink the forestry sector’s carbon footprint, help companies meet rising sustainability demands from customers, and prepare the industry for tightening EU regulations.

A major step toward this future will be taken in Kemi, a coastal town in northern Finland’s Lapland region, in the second half of next year. Metsä Group and logistics company Pohjaset Ltd. will launch Finland’s first pilot of electric timber transport as part of the ACE project. The goal is to test the performance of electric heavy-duty vehicles in real timber-haul operations.

The electric truck-and-trailer combination will run between the Laivakangas terminal in Tornio and Maksniemi terminal in Simo and the Metsä Group Kemi bioproduct mill—exactly the type of predictable route where electrification has the greatest potential.

Kari Poikela, Business Development Director at Pohjaset Oy, highlights why this test matters:

“We want to test the electrified timber truck combination in Arctic conditions. If it works in the freezing temperatures and challenging conditions of Lapland, it should work anywhere,” Poikela says.

The pilot will gather data on energy consumption, driving range, charging cycles, and equipment utilization—critical insights that will reveal not only how well electrification works, but also where its limits lie.

Electrification gains ground in factory operations

Electrification is progressing fastest within factory areas, where short, predictable routes make it easier to install charging infrastructure. In November, Stora Enso tested an electric wheel loader at its Anjalankoski factory as part of the ACE LIFE project, and the results exceeded expectations, showing lower emissions and reduced operating costs compared with diesel models.

“The electric wheel loader’s charging station was connected to the factory network without any major investment. Charging is, in fact, much simpler in internal factory operations than on public roads,” says Niko Hannula, who managed the pilot at Stora Enso’s Anjalankoski facilities.

The loader was pushed to its limits: the battery was fully discharged, charging was carefully monitored, and drivers evaluated its performance under real working conditions. The results were clear—charging posed no problems, the battery performed as promised, and the electric motor delivered sufficient torque. The only limitation was with high-energy attachments, such as large brush machines, which were not operationally viable on the electric loader, Hannula notes.

From a financial perspective, the pilot brought a welcome surprise.

“Fuel and maintenance costs are significantly lower than with the diesel option. Over the contract period, the electric machine may even be more profitable than the diesel one,” Hannula notes.

UPM has also begun electrifying heavy transport, starting from the “easiest” application: internal transport within mill complexes, explains Janne Uuttera from UPM.

Currently, electric vehicles transport by-products from the Alholma sawmill in Pietarsaari to the pulp mill. For this project, UPM installed on-site charging infrastructure with co-financing from the ACE project, while the terminal operator, Oy Adolf Lahti Yxpila Ab, purchased the vehicles.

According to Uuttera, electrification will eventually extend to wood supply transport as well. Initial focus is on regular, predictable routes—such as by-product transfers between factories or between terminals and mills. Electrifying raw wood transport from forest storage to terminals or factories will remain challenging until high-power charging networks are more comprehensive, and until current electric vehicles are better suited to rough forest roads, Uuttera adds.

Sweden leads the way

So far, Sweden is ahead of Finland in the deployment of electrified timber transport, largely thanks to the home-ground advantage of truck manufacturers Scania and Volvo. These companies are testing new equipment on their domestic market, and the forest industry has also joined the trials with bold initiatives. Sweden’s charging network for heavy transport is also significantly more extensive than Finland’s.

Forestry group SCA and truck maker Scania are among players advancing Sweden’s electrification of timber transport. The first electric timber truck, introduced in 2022, has been hauling logs between SCA’s Gimonäs terminal in Umeå and the Obbola paper mill.

A second vehicle joined the fleet in October 2024, this time operating directly in the forest. Unlike the Umeå truck, the new model is equipped with a crane—standard for timber trucks that collect logs at storage sites.

“Our new electric timber truck has a better range and drives to timber storage areas in the forest where it loads timber for further transport to our terminal in Östavall. We expect it to cut carbon dioxide emissions by 170 tonnes per year compared with a regular timber truck,” said Anton Ahlinder, Business Developer at Industrial Supply, SCA Skog, in an article on SCA’s website.

Sweden’s innovation agency Vinnova is funding pilot deployments, including the flagship TREE (Transition to Efficient Electrified Forestry Transport) programme that ambitiously aims for half of new forest trucks to be electric by 2030. Still, adoption remains slow: in 2023, only 3 percent of new trucks sold were electric, far below the 2030 target of 50 percent.

“Charging the logging trucks and transport planning are two important pieces of the puzzle,” said Gunilla Ölundh Sandström, Associate Professor at KTH Royal Institute of Technology, in an interview with KHE.se, noting the challenges of building charging infrastructure in remote areas and the need to rethink logistics.

Biogas trucks already rolling in Nordic forests

While electrification is seen as the long-term solution for forestry logistics, biogas has already proven to be a viable alternative fuel. In Finland, more than a dozen timber trucks are already running on biogas, which can be produced from forest industry sidestreams.

Research shows that biogas-powered heavy-duty vehicles perform well on gravel forest roads—routes that place unique demands on transport equipment and run precisely where biomass is moved from forests to industrial processing facilities.

Finland, Sweden, and Norway are emerging as pioneers in integrating liquefied biogas (LBG) into their forest-based bioeconomies. In June 2022, Finnish transport company Eskola Ltd. (Kuljetusliike Eskola Oy) launched Europe’s first heavy-duty biogas-powered timber truck in the Oulu region, operating in partnership with Metsähallitus, the Finnish Forest Administration responsible for state-owned forests, according to a Forest.fi article.

Despite the potential of electrification and biogas, the transition to zero-emission forestry transport will take time. High vehicle costs, limited charging and fuelling infrastructure, and the relative immaturity of the technology are slowing widespread adoption. However, pilot projects, EU climate targets, and growing corporate investment are steadily driving progress.

The next decade will be critical in determining how quickly Finland—and the broader Nordic forestry sector—can move from fossil fuels to electric and other zero-emission transport solutions.