Blog by Niko Hannula: Reducing emissions during transport of timber from forest to mill

Electric harvesters and forwarders at work in the forest, less noisy timber lorries being loaded on a logging road. Is this just a pipe dream or a development we should take seriously?

By the end of the decade, the above scenario could be quite a common sight for those visiting a forest, now that low-emission energy sources are being looked for to power machines and vehicles in the forest industry supply chain.

To a great extent, fossil fuels are still used today in harvesters and timber lorries, as well as in the machinery used to handle timber at mills and terminals. This, however, is set to change. A number of forest industry actors have decided to join forces and participate in a project called Accelerating Climate efforts and Investments (ACE).

Funded from the European Union’s LIFE programme, the ACE project supports the goal set for the reduction of emissions from the effort-sharing sector by 2030, and the goal of reaching carbon neutrality by 2035.

The desire for change was evident at Stora Enso’s Imatra mill in May, as a number of experts and mill workers examined an articulated lorry used for timber transport inside the facility. Many different vehicles and machines are used in the facility, and replacing their diesel engines with alternative sources of energy is currently being studied (Image 1). With operating practices honed to perfection over several years and a skilled crew, it is quite a challenge to try and reduce emissions further with just the current equipment. Stora Enso is thus keen to look for new innovations in timber transport within its own supply chain from forest to mill.

Drivers and operators assisted by new systems

For Stora Enso, an important part of the ACE project is also to develop systems to assist drivers and operators, as well as to enable the automatic gathering of information from forests and the transport of raw timber.

Parallel to current calculation models, what are needed are more accurate and updated figures to enable an overall development of activity. Improving the definition and monitoring of the current level will help to reveal the impact of decisions on the carbon footprint of deliveries.

In developing the systems, the focus will increasingly lie on an automated gathering of data, as the drivers and operators already have a number of tasks and are not likely to want any more buttons to press during the workday.

One of the ambitious goals is to improve the systems so that drivers and other workers in operative tasks can assess the impact on emissions of their actions on the spot.

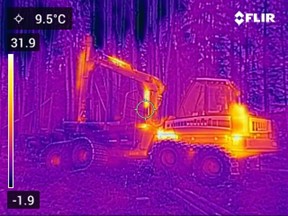

Infrared photography detects extra consumption of energy

Due to the high rate of utilization, machinery today is subject to severe mechanical stress. The maintenance of machinery is extremely important but, especially in the dark of winter, something like small changes in fuel consumption is difficult to notice while working.

Infrared photography is one of the solutions tested to solve this (Image 2). It is used to detect excessive heat in power transmission components, possibly caused by stones or fallen twigs being jammed between moving parts.

Stora Enso is planning to extend the use of infrared photography to cover not only harvesters, but also timber lorries, to keep the wheels turning without hitches.

Nor are useful innovations necessarily digital. We do still need simple solutions that work in the field, in addition to digital solutions. Such low-tech innovations are the result of collaboration, for which the ACE project provides good support.