Air vents in facades open and close autonomously according to weather – ’Sounds like science fiction, but it’s real’

A facade element made of wood foam can bring in considerable savings in heating and cooling. The research project has received millions in funding and a pilot plant is being planned.

When a facade element made of wood-based foam contracts and expands owing to changing temperatures and humidity, the building is cooled or heated. The motion of the elements causes the round air vents in the facade to open and close, which reduces the need for heating in cold weather and for cooling when it is hot.

’It sounds like science fiction, that the air ducts could open and close as part of a natural process, but it’s real and exciting stuff. ’ says Dr. Juha Koivisto, Research Fellow at Aalto University.

Wood foam elements for buildings are being developed in the Archibiofoam project led by Aalto University. The project has received a three-year Pathfinder Grant of EUR 3.4 million from the European Innovation Council.

The aim is to reduce the climate emissions from construction, which make up 40 percent of global emissions.

Wood foam is an application of ’Physics 101’

The action of a facade element made of wood foam is, in Koivisto’s words, based on ’simple basic physics’, the same as that applied in thermometers in Finnish saunas. They are a combination of two metals that expand at different rates when heated.

’Since one of the metals expands more, the thermometer pointer moves accordingly in the desired direction and indicates the temperature. This is based on the same idea. We make different foam materials which expand or contract according to conditions in their environment,’ Koivisto explains.

The different materials steer the action in the desired direction and regulate the ventilation in the building according to the weather.

In addition to the materials, the project researchers also develop ventilation chamber mechanisms. Models for the mechanisms have been looked for in origami, the traditional Japanese art of paper folding.

Juha Koivisto was inspired by the architecture of Antoni Gaudí in Barcelona. He says that Gaudí’s work is characterized by natural motion, bending and arcing, which are more frequent in nature than linear movement or rotation.

’Gaudí’s beautiful architecture in Barcelona is really very organic. The facades are not straight-angled but rounded, and emulate nature. This is the point of contact with my invention,’ says Koivisto.

Wood foam is almost nothing but air

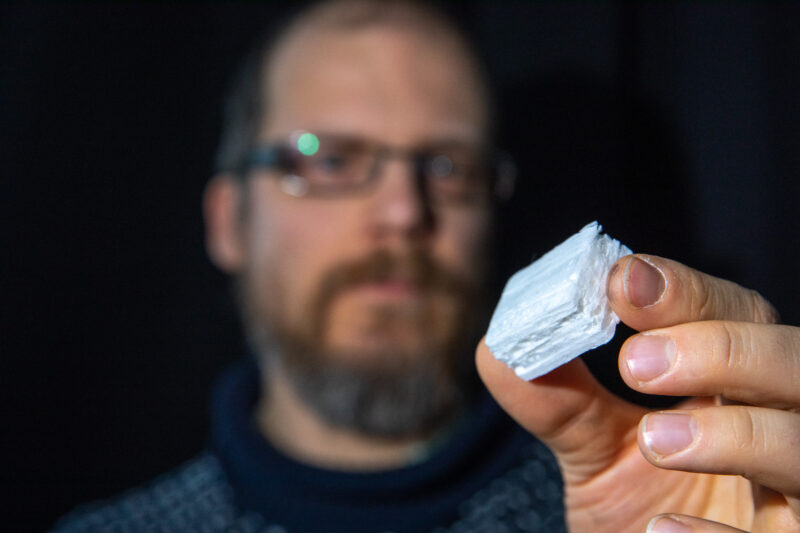

Wood foam is 90 percent air, but its strength is comparable to that of concrete or glass. In addition, it is renewable, biodegradable and recyclable. The material has been researched at Aalto University for a decade.

’The scientific community has known for some time that the structural integrity of these biofoams is competitive with other construction materials, but it hasn’t been tested to its full potential,’ Koivisto says.

The product is 100-percent wood-based, but other materials, such as straw, can also be used besides craft pulp.

’Wood foam is made of forest-based raw materials,’ Koivisto says.

’The basic method of production is to take pulp, cellulose ether and additives that improve resistance to water. Of these, a suspension [water solution] is made, which is then whisked to a foam and dewatered. In the resulting foam the cellulose molecules form the supporting structure, and the cellulose ether forms a system of membranes which keeps the fibres together,’ Koivisto explains.

Interestingly, the method can also be used to manufacture edible snacks.

‘The method can be used to make foam out of powdered carrots, cowberries, cranberries or beetroot, and that can be further processed into crisps which resemble potato crisps,’ as Koivisto said to forest.fi in 2021.

The industrial partner in the project is the startup company Woamy, a spin-off of Aalto University, which develops packaging materials of wood foam. The company aims at starting a pilot plant for making wood foam elements by 2027.

Koivisto says that when started, the pilot plant would provide dozens of jobs. The plant could be located on one of the bio plant sites operated by the forest industry in Finland. When completed, it would provide work for dozens of highly skilled people.

Read more: Use of AI in the forest sector illustrated in six images