We listed six innovations from the Finnish bioeconomy which reduce the use of fossil raw materials and enhance recycling.

1. Wood in batteries of electric cars

Graphite, a synthetic and non-renewable material, can soon be replaced by wood-based biocarbon in rechargeable batteries. The innovation by Stora Enso can be used in electric cars, consumer electronics. large systems for energy storage, as well as for other purposes. The product was launched last year.

Lignin, which is extracted from coniferous wood, can be processed into renewable materials for anodes that are required for the functioning of rechargeable batteries.

![]()

![]()

![]()

![]()

![]() According to forecasts, the global market of batteries will increase tenfold in ten years.

According to forecasts, the global market of batteries will increase tenfold in ten years.

Stora Enso started its pilot plant to manufacture bio-based carbon materials at its Sunila facility in Kotka, south-east Finland, in the summer of 2021.

The Kotka biorefinery has produced lignin since 2015. The refinery capacity is 50,000 metric tons of lignin per year, making Stora Enso the world’s largest producer of extra-dry lignin. After cellulose, lignin is the most prevalent macromolecule found in nature.

2. Recycled stickers for bananas

When buying fruit and vegetables, you can now print out a price sticker for them that is made of recycled wood fibre.

New thermal paper labels for use in retail and wholesale businesses were introduced last autumn by UPM.

These labels are used in weighing scales for fruit and vegetables, in salad and meal packagings and for logistics labelling needs. No virgin wood fibre is used in the labelstock, and it is free from toxic phenol.

UPM points out that using recycled papers reduces the use of new wood in forest industry products.

‘The need to reduce waste and alleviate the pressure on virgin raw material sources is evident and increasing,’ says Ville Pollari, Director of Business Segment VIP & Prime at UPM Raflatac.

‘Making the switch to these labels offers a host of sustainability benefits for both the brand owners and the environment,’ Pollari continues.

3. Wood reduces use of concrete in construction elements

A new hybrid element combining wood and concrete helps to make construction more ecological.

The element consists of a wooden Kerto LVL board made by Metsä Fibre, a layer of heat insulation and reinforced concrete used for the facade. Designed jointly by Metsä Fibre and partners, the element resembles a sandwich in its structure.

The new element was first used last autumn when constructing Metsä Fibre’s new sawmill in Rauma, western Finland. The construction work of the sawmill facility was delivered by Skanska. The company says that the new, partially wooden element is installed in the same way as wall elements made of reinforced concrete, but is lighter in weight.

‘We were able to use a smaller crane in the installation work, since the hybrid wall elements are lighter than conventional concrete elements. In larger construction projects, less weight can bring substantial savings,’ said Construction Manager Petri Puputti in a press release by Skanska in October.

Skanska aims at being a globally carbon neutral company by 2045.

‘The Rauma sawmill project gave us useful first-hand knowledge of using these elements in construction. It seems these elements are well well compatible with our technical needs,’ said Ilkka Romo, Director of the Productivity and Quality Unit at Skanska, in Metsä Wood’s press release in October.

The elements were manufactured by Lipa-Betoni in South Savo, eastern Finland.

4. Wooden satellite with selfie stick

In April 2021, an ambitious project was announced by UPM and space experts. The first wooden satellite in the world will be launched to orbit the Earth in the first half of 2022.The launch is scheduled to take place at the Rocket Lab in New Zealand.

Made of plywood, the Wisa Woodsat nanosatellite is designed and built in Finland. It is a little solar-powered cube with 10-centimetre edges that almost fits in the palm of your hand.

The satellite is used to test the suitability for space craft of wood, and particularly of UPM’s WISA-Birch plywood made in Savonlinna, eastern Finland. Up in space. the plywood will be exposed to heat, cold, vacuum and radiation. It will be observed by two cameras, one of which is placed at the tip of a boom deployed in space.

‘A satellite with a selfie stick is sure to attract positive interest and raise smiles, but at heart this is a serious scientific and technological project,’ said Jari Mäkinen, leader of the WISA Woodsat project, in a press release by Arctic Astronautics in April.

The WISA birch plywood is in general use in shipbuilding, automotive industries, construction and furniture making.

In addition to plywood and other things, the satellite will test cost-effective satellite telecommunications technology.

UPM is developing the WISA Woodsat satellite in collaboration with the Finnish company Arctic Astronautics, the European technology design company Huld and the European Space Agency.

5. Less carbon in baby nappies and feminine hygiene products

Paper napkins, baby nappies and incontinence and menstrual pads, those most mundane and familiar things, can soon become more ecological. In October, Stora Enso launched a lower-carbon fluff pulp used to manufacture absorbent hygiene products.

According to Stora Enso, the carbon footprint of the new NaturaFluff Eco pulp grade is about 30 percent less than that of conventional absorbent fluff pulp, thanks to the absence of chemical bleachers in the manufacturing process. The pulp is light brown in colour and is said to be fully biodegradable.

‘By removing bleaching from the production process and only treating the pulp with oxygen to remove lignin, we have produced a fluff pulp with a significantly lower carbon footprint, while still providing the excellent performance of our regular fluff pulp,’ says Kirsi Seppäläinen, SVP Marketing, Competitive Intelligence and Product Management at Stora Enso’s Biomaterials division

6. Recycled bed sand clarifies water

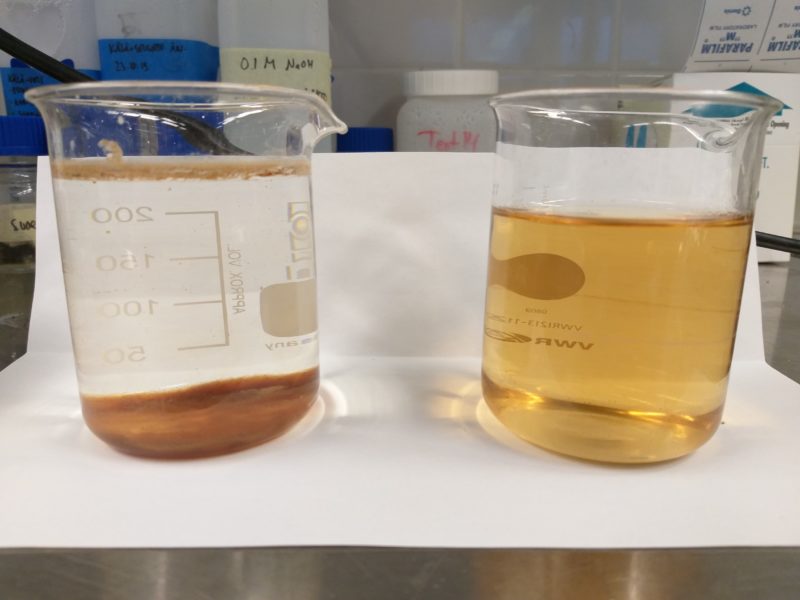

2021 brought good news to all lovers of crystal-clear waters. Brown water, scooped out of a peatland ditch, became clearer when treated with bed sand previously used in a bio power plant, as was announced by Metsä Group last summer.

‘Humic substances reacted with substances in the sand, forming complexes that could be removed,’ said Vesa Junnikkala, Director of Sustainable Development in a press release by Metsä Group in June.

According to VTT Technical Research Centre of Finland, elements contained in the bed sand include potassium, aluminium and iron, which are known to combine with humic substances.

‘In particular, the bed sand treatment reduced the chemical oxygen demand in water, as well as the amount of coloured particles,’ says researcher Joni Lehto at VTT.

Improving the clarity of waters is of interest since the restoration of peatlands causes leaching of organic substances that are difficult to remove downstream. The substances stain the water brown and increase the biological oxygen demand.

The bed sand was also tested in a small-scale field experiment.

The project results were published last spring in the journal Environmental Technology. More testing is required before a more widespread practical use of the method.

One comment on “Wood in batteries of electric cars, clarification of runoff from mires… Six hot innovations from Finnish bioeconomy”

/ Heinrich Gratenau

Vers interesting how the use of natural fibres is develeopad and replaces non renewables.